|

|||||||

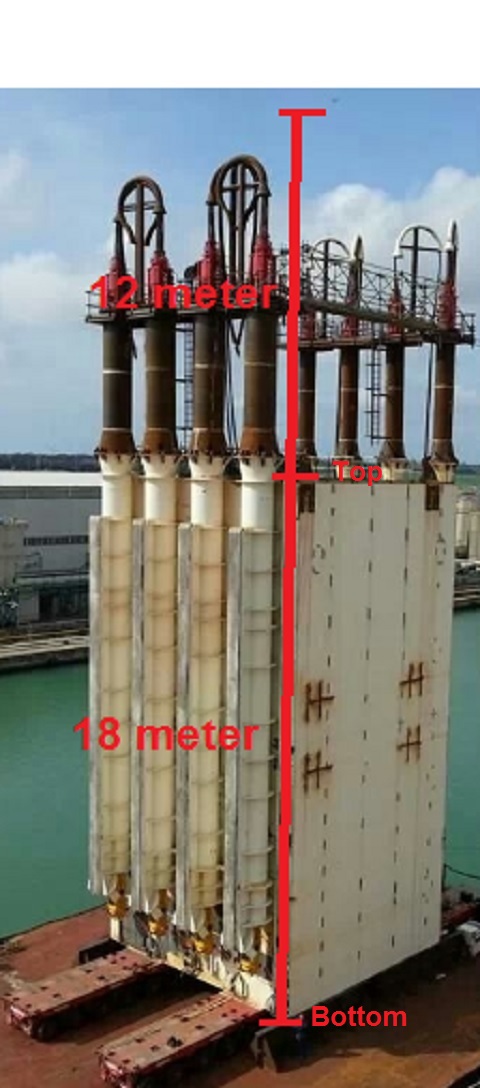

45 000 tons of ship with draught 11.36 meters was July 2014 removed from the rocks of Isola del Giglio and brought to Genoa |

|||||||

|

|

|

Welcome

to Part 11 of my Costa

Concordia incidents January 13-14, 2012

caused by ship not being

seaworthy

report continuously updated.

This

page explains the absolutely

amazing scandal how a 45 000

tons ship (not a wreck) was (1)

removed from rocks outside Isola del

Giglio January 2012 - July 2014 for

scrapping and recycling at

Genoa, (2) how the deck house and

superstructure along a jetty were

emptied of outfit and then cut off from

the ship and transported away

somewhere and (3) how finally the

17 000 tons hull of the

ship with engines, crew

accommodation, fuel tanks (emptied already

2012) and full of toxic waste was 1

September 2016 put in drydock, where it

later, suddenly just disappeared ... it

was towed to sea and sunk after hull being

repaired ... April 2017! It also explains

who paid US$.1.500.000.000:-

for it. Of course it was not applied in mafia controlled Genoa! In this case the parties involved - the ship owner, subcontractors, underwriters, P&I clubs, government agencies, etc, didn't follow any rules and regulations at all. It took 3 years to remove the 45 000 tons ship from Isola del Giglio to Genoa. 28 000 tons of deckhouse and superstructure were then removed along a jetty between July 2014 and August 2016, or ~1.100 tons scrap/month. Not bad! Easy job. It was done! But once in drydock 1 September 2016 ... 17.000 tons of dirty hull with engines, three decks of crew accomodation, stores, etc, having spent four years below water just disappeared by May 2017, i.e. >3 000 tons scrap/month was removed! It was not done! It was Magic! And even worse. All signs of the company that scrapped/recycled the ship disappeared April 2018. Only evidences of scrapping and recycling of a ship in drydock are some strange photos. On 30 March 2017 Google Earth took a photo of the ship in drydock at Genoa:

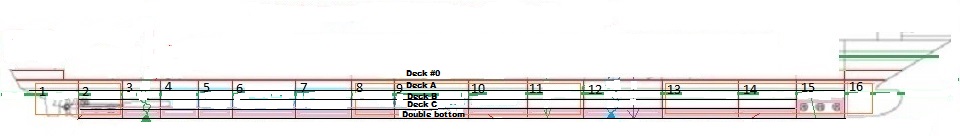

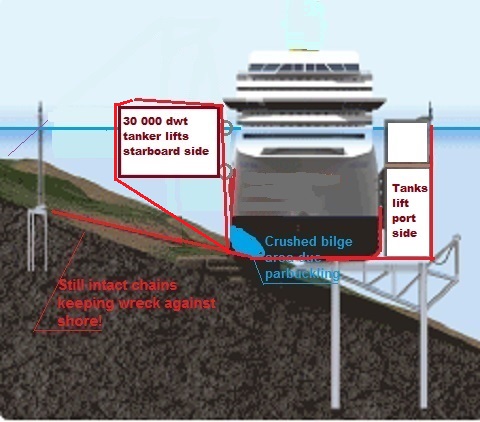

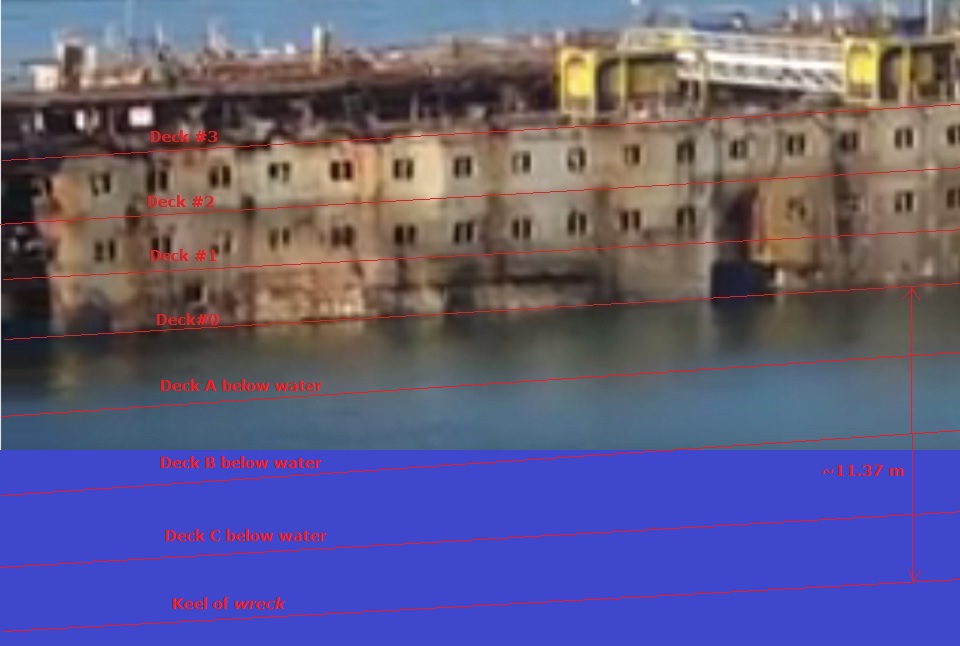

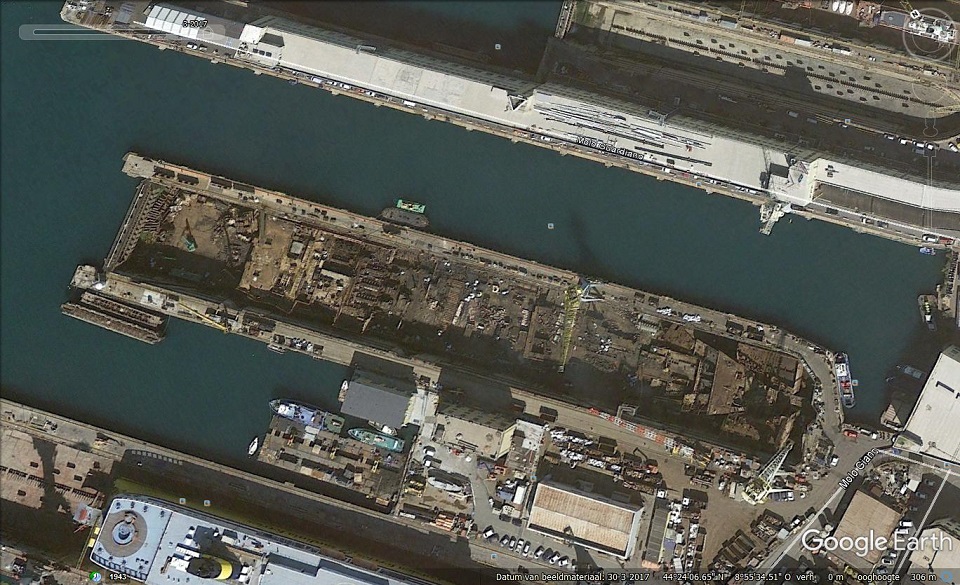

Note that the ship has beam 35 meters and that it almost filled the full width of the drydock. It seems there was plenty ship left in the drydock then. The engines generators/electric motor rooms occupy about 45% of the aft part of the ship. The ship was diesel electric! Forward of the forward diesel engines are three electrical generators. Aft of the aft diesel engines are another three electrical generators. Aft of the six engines/generators are two electrical motors driving the propellers/shafts. To assist understanding some drawings of the top of the double bottom are shown below.

However, below is a photo of the drydock at Genoa May 2017. No ship! No engines! No generators. Not even any blocks on which ships normally rest in drydock. Just various scrap steel still in the dry dock bottom. The photo is fake!

A drawing of deck #0 of the aft part of the hull is:

Another fake photo of unknown date (mid April?) of it is:

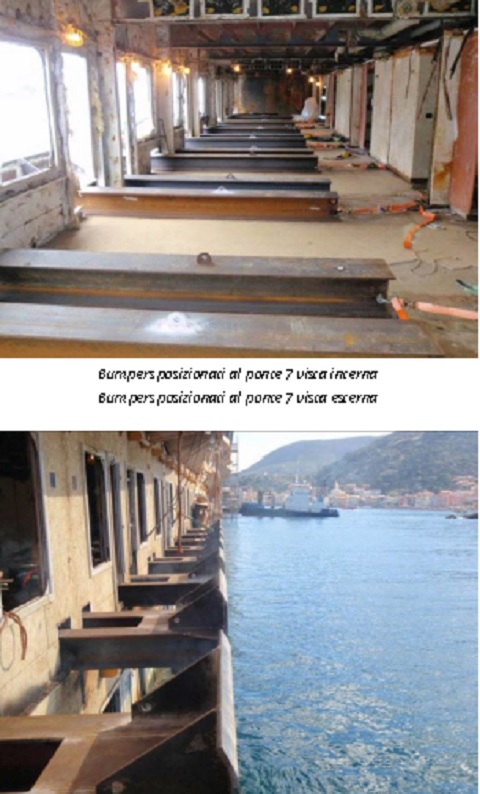

Do you see six main engines, six generators and two electrical motors? No - because the photo is fake! Note also that no 300+ workers are seen and that the bottom of the ship rests straight on the concrete floor of the dock. There was no way to empty the double bottom tanks through the plugs in the bottom! When workers cut the bottom plates - from inside? -, they also cut the concrete floor. But no sign of it. Where is the steel cutting equipment? Actually, the whole aft end of the ship aft of the electric motors room is not there! The photo is fake! The bilge/side parts of the ship outside the engines/motors have also disappeared. The port side contained the famous side damage that flooded the ship. It was apparently just cut off and lifted up and ... disappeared. Actually what is left of the ship is not located at the centre of the drydock. The photo is fake! So suddenly - on a photo - only three aft engines with no generators were left ... at the end of the drydock! But they do not look like the engines fitted on Costa Concordia! And the electrical motors further aft driving the propellers/shafts don't look like electrical motors. And what happened to the steering gear room and the aft peak? IMO the photo is 100% Photo shop fakery! What had become of the hull of the rest of the ship with all toxic waste, etc? Mailonline had an article with plenty photos about the ship 14 January 2017. If you could only lift 5 tons with a mobile crane in the drydock bottom, the ship must be cut in 3.400 pieces (of 5 tons), each to be lifted up and away. If this took place in 4 months time, 38 pieces/day or 190 tons/day were disposed of! But how and where? I have tried to ask Mr. Franco Porcellacchia, Vice President, Carnival Corporation & PLC, Genoa, Italy, what really happened. It seems that 2012/7 >3.000.000 fake invoices have been paid in connection with the incident. Three million invoices! For a simple CTL, Constructive Total Loss of a ship claim! It is one invoice! Plus removal costs. And re-cycling costs. And costs to replant sea weed at Giglio. Paid by whom? The various underwriters? But the ship was not seaworthy and the insurances were not valid 2012. Mr. Franco Porcellacchia thinks 2018 it is better to forget the whole thing as fast as possible as an Italian is in jail, guilty of everything. The Master. Francesco Schettino. I had 2017 suggested that the drydock with ship should become a museum: Guided tours

Tuesday-Sunday (Monday closed) could be

arranged every two hours starting at

09.00 hrs and then 11.00, 13.00 and

15.00 hrs. The guide could be no other

than ex-commandante Francesco

Schettino himself, who knows

the ship inside and outside. He will

demonstrate how to close a watertight

door! At present Francesco

Schettino however spends 16

years in jail! "Genoa, 7 July 2017 - The dismantling and recycling of the Concordia cruise ship, one of the most important green ship recycling projects ever carried out in Europe, has been completed (!) in Genoa by San Giorgio del Porto, in partnership with Saipem. So the ship and its toxic waste, etc, etc, finally disappeared July 7, 2017! But there is no evidence that 16 950 tons of steel was sent anywhere for recycling January/April 2017 and that 50 tons of toxic waste was taken care of! No invoices! Because January 2017 there were still 17 000 tons of it in drydock #4 at Genoa. In my opinion one possibility is that the 35 m long structural damage in the port side was patched up watertight in drydock September 2016 - March 2017, so the hull could float again, and that, one dark night April 2017, the drydock was filled with water and ... what remained of the ship was towed away to sea ... and sunk! The famous watertight doors were of course open ... again. Will we ever know? It is a great story. But not in Italy! The Mafia assisted by the Port of Genoa did it! There are no invoices! It is very easy to prove me wrong: Just provide photos of the ship in drydock every week January/May 2017 and tell me how you cut the bottom shell plates in the double bottom resting straight on the drydock concrete floor! From inside the double bottom? But it is full of girders and floors ... and shit! All the photos above of the main engines and an empty drydock are fake? And what about evidence of all toxic waste being removed. There is none! Not even invoices! Of course there were 3 million invoices paid but ... it was fantasy!

But Mr. Franco Porcellacchia, Vice President, Carnival Corporation & PLC, Genoa, Italy, has confirmed the ship was the responsibiliy of Carnival Corporation & PLC, Genoa, Italy. I therefore suggested that the ship in drydock became a museum of unseaworthy ships, while the judiciary sorted out who owns what and who is responsible for what happened. It never happened. The ship was towed to sea April 2017 and sunk again. It should be fairly easy to locate that ship again ... at the bottom of the sea outside Genoa. The master, Francesco Schettino, of the ship was sentenced to 16+ years in jail being totally responsible for the allegedly criminal incidents described previously; accidental contact 13 January 2012, badly executed Abandon ship with himself first off the ship, capsize, sinking, killing 32 persons, causing a shipwreck (? - it was always a stranded ship!) and damaging the environment the next day 14 January 2012, etc, etc. It has been established by corrupt/criminal Italian judiciary and maritime experts that all was the fault of the Master Francesco Schettino alone, who must spend 16+ years in jail ... unless the Italian Supreme Court of Cassation Friday 12 May 2017 decided that a complete new trial is required and that the museum can be created! Schettino has appealed and lately suggested that illegal watertight doors sank the ship! Schettino thought the ship at departure was seaworthy and that it was 100% safe after the accident but then ... watertight doors were opened by escaping staff and ... disaster! Capsize and sinking! Friday 12 May 2017 it was decided to jail Schettino! The legal reason was that according to an Italian law made 1942 during the Mussolini rule the Master of any Italian ship is responsible for everything. The ship owner or the Designated Person Ashore is responsible for nothing. But maybe the museum will be done? Or not! It seems the ship was suddenly 100% recycled June 2017 at Genoa: Five years after the Costa Concordia shipwreck in 2012, ship demolition operations and removal of interior fittings continue. "We are in the final stages of the demolition, which will end by June 2017," Paolo Trombetta of the San Giorgio del Porto Communication Office told media. If this is true, the demolition in drydock was at a rate >200 tons/day. Magic! But media never checked what went on in the drydock. My simple opinion is that Francesco Schettino is completely innocent of any wrong doings. He just followed instructions given by the ship owner. The ship was not seaworthy at departure with full knowledge of owner, authorities, experts ashore, hull underwriters and ... media. Regardless, below is a clear description how criminals of all kinds are destroying serious attempts to improve safety at sea worldwide, while stealing money from underwriters and re-insurances. With media looking away! The whole thing is today just a big, sad joke! Let's repeat: 24 December 2016 the hull of the ship in drydock (!) was being cleaned to enable final recycling but no photos of inside or outside could be provided ... 5 June 2017. Imagine cleaning the inside of a ship full of, e.g. rotten food that has spent >4 years below water! Normally you only put ships in drydock on blocks ... to clean the outside of the hull! And the scrapping company is not on the list of EU approved ship recycling facilities! And who has ever heard about scrapping ships in a narrow drydock ... full of water? Normally old ships are run up and scrapped on a flat sandy beach with plenty open/flat space around. Bits and pieces are cut off dropping down on the ground and pulled away from there, etc, etc. It takes a very short

time to scrap any ship that way, but you

need

10.000's

of workers to do it. But how was it done at

Genoa, Italy? Bits and pieces were

cut off by 100 idiots and lifted with

cranes to be put on barges or trucks, bla,

bla, bla. It should take ... a

long time? 28 November 2016,

i.e. 4 years and 10 months after the

incidents, it was suggested that the

salvage/removal/recycling of the

M/S Costa Concordia

ship had cost

$1.200.000.000:-,

while 17 000 tons of the

ship was still full of shit

in a narrow drydock at

Genoa. Only

28.000

tons of the ship

deckhouse had so far been

removed in big pieces, put on barges

and put ashore somewhere for cutting

up/recycling. A simple job. Further

details ... unknown! How is this

possible? Who is

paying for this? The ship

was not seaworthy and no

insurances were valid 2012! Who paid?

The shipowner? The insurances? The tax

payers? No - the H&M underwriters and

the International

Group of P&I

clubs paid!

Without checking anything. And today the

latter has no records at all about the

case! Why

would anybody pay

$1.200.000.000:-

to put

17.000

tons of shit on the floor of a

drydock September 2016? And pay

another $300 000 000:- to sink it in the

Mediterreanean Sea 2017! 24

December

2016 we

were told by the recycling

consortium that

Maybe better is just to pump the dock dry, clean up the ship and make the whole thing a museum (drydock + ship)! People can visit the accommodation, where crew worked 11 months/year at slave wages hardly seeing the sun, while others were wining and dining up top. You could also see the illegal watertight doors, the little damage in the side and be told why the ship sank due to progressive flooding of undamaged compartments. You could also visit the engine rooms. It would be quite interesting

Hot work - cutting - is done up top, while cleaning lower decks are still going on. But is cleaning lower decks really going on? It would be interesting to know how to light, ventilate and ensure that the lower decks are gas free during these operations. I assume that the bottom of the drydock is still full of dirty water to prevent any gas filled spaces there to explode. How long the final operations will last was not known. My 2016 estimate was seven (!) years and probably >$40 000 000:- additional costs. I was wrong. There was no scrapping at all. Only the hole in the port side was made watertight and one night April 2017 the ship was towed out to sea and was ... sunk! Cost? $300 000 000:-! Imagine 150 workers descending into the hull in the drydock half full of water every day manually cutting decks up top, cleaning double bottom compartments below water, removing and sorting outfit of all kind and so on. What a stupid job. They never existed! You should of course ask what people and companies are involved in this nonsense. The Concordia ship Ship Recycling Consortium was formed by Saipem (51%) and San Giorgio del Porto (49%). These two companies joined forces in September 2012 with the aim of providing services in the field of "Green Ship Dismantling" (i.e. environmentally and socially sustainable dismantling of end-of-life ships) in Genoa/Italy. Their motto was: "The project of dismantling and recycling of the wreck of the Concordia is the most challenging ship dismantling operation ever carried out in Italy and, in all likelihood, worldwide, in terms of both the size of the vessel and the condition in which the wreck is afloat." Thanks to its technical and management expertise, Saipem said that it guarantees supervision of the environmental aspects of ship dismantling projects; its services include monitoring, environmental protection measures, oil spill response, remediation of areas and infrastructure as well as waste disposal and recycling, we are told. San Giorgio del Porto has the right to use major (?) ship demolition and recycling assets (sic) in the ports of Genoa and Marseille (sic). It is the first shipyard to be listed on the Italian Ministry of Infrastructure and Transport's Special Register of Environmental Ship Reclamation & Recycling Facilities. Why not? But are they listed to recyle ships at Marseille, France? Or anywhere? And are there any ship demolition assets in Genoa? The Ship Recycling Consortium said it works according to the International Convention for the safe and environmentally sound recycling of ships and that it has an Integrated Environmental Authorization for dismantling and recycling of the Concordia; it is duly certified and authorized with regard to the two companies' respective Quality, Environmental and Safety Management Systems (9000/14000/18000) and also has specific ISO 30000:2009 certification for Ship Recycling Management. However the companies and their consortium are not even on the list of EU approved ship recycling facilities and the Convention referred to is not in force anywhere. April 2018 this mysterious Ship Recycling Consortium and its directors disappeared completely. Nobody knows if it ever existed, kept accounts and paid taxes, etc. Media have not reported anything serious about this. Media only told and tell you rubbish and Fake News! The Concordia three years ship disposal 2014/7 along a jetty and in a drydock half full of dirty water at Genoa, Italy, had nothing to do with environmentally and socially sustainable dismantling of an end-of-life ship. It was a hoax! If you are interested in the Truth, you have to read about it here. A quick re-cap: Francesco Schettino was the Master of the cruise ship M/S Costa Concordia and appointed by the ship owner. The Master is the representative and top servant aboard of the ship owner ashore. He and his crew work according principles of the SOLAS International Safety Management, ISM, code established by the ship owner as job descriptions, etc. It had been decided

before departing Civitavecchia

19.18 hrs on the way to

Savona to pass close to the

Giglio island at 21.45 hrs,

i.e. in the early but dark

night. To do so you evidently

at departure set

course

straight for the Giglio island

(e.g. passing south of Giannutri

island on the way) to pass Giglio's

east side from the south at a safe

distance ... without turning (figure left)

... but NO! The ship went straight

for Savona at departure and only

later, during the leg between

Civitavecchia and Savona,

some officers aboard turned the ship

port

straight

towards the

Giglio island for the Master to

carry out a

sharp

starboard turn

at the last

moment to impress the passengers & Co.

Of course most passengers aboard

were not told about it!

So just before all

incidents that followed the

ship was heading

perpendicular

towards the Giglio island ... and

the Master forgot to turn

starboard correctly ... is the

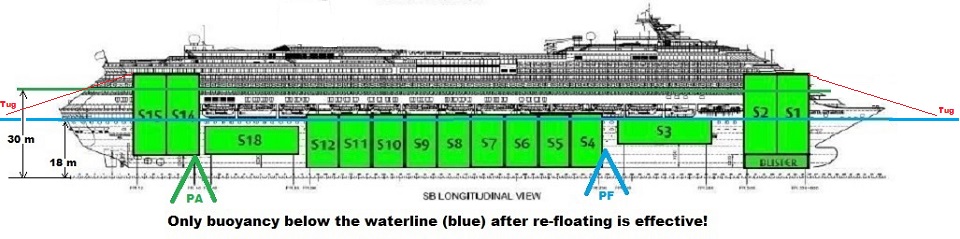

story! However, at 22.26 hrs the Master advised the Livorno Maritime Rescue Sub-Centre (MRSC), that the ship was taking in water and was listing. The starboard bilge touched some rocks about 22.33 hrs. Anchors were dropped. The situation was in the meantime reviewed as per ISM. Contact with HQ ashore was made. It was decided to put passengers and staff abord ashore. So the lifeboat alarm, i.e. the General Alarm was raised at 22.33 hrs (48 minutes after the first incident!) to prepare for Abandon ship starting at 22.54 hrs (21 minutes later). It meant that the Life Saving Appliances, LSA, were going to be made ready starting at 22.33 hrs and all passengers and staff were supposed to gather at the muster stations to be escorted from there starting at 22.54 hrs. At 22.48 hrs the Master of the Costa Concordia asked the MRSC for tug assistance to tow the ship to a port for repairs. It seems the Master tried his best to save the ship as per ISM. 14 January, 2012 the ship, after a badly executed evacuation/abandon ship operation, suddenly capsized ending at the side say 00.22 hrs and started to sink 00.34 hrs and slowly partially sank on some rocks near the shore of Isola del Giglio and 32 persons drowned. It seems watertight doors were opened after the incident by escaping staff causing further loss of buoyancy and total stability. The ship soon became insurance wise a constructive total loss. Francesco Schettino, the Master of the ship, was, however, immediately arrested, handcuffed and jailed when coming ashore. That is a fact. All was his fault! He was incompetent, killed people, abandoned and sank the ship with passengers aboard not to drown himself and damaged the environment, etc, etc, he and we were told by media and the ship owner! After three days in jail the Master was released. He was under shock! Still is! He just followed orders and ISM instructions after the accidental contact. This was clearly against the DIRECTIVE 2009/18/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 23 April 2009 para (9) which says: Seafarers are recognised as a special category of worker and, given the global nature of the shipping industry and the different jurisdictions with which they may be brought into contact, need special protection, especially in relation to contacts with public authorities. In the interests of increased maritime safety, seafarers should be able to rely on fair treatment in the event of a maritime accident. Their human rights and dignity should be preserved at all times and all safety investigations should be conducted in a fair and expeditious manner. To that end, Member States should, in accordance with their national legislation, further take into account the relevant provisions of the IMO guidelines on the fair treatment of seafarers in the event of a maritime accident. Later the ship owner fired the Master from the company and conspired, assisted by P&I, so far succesfully, with the Italian judicial authorities that condemned him to 16+ years in jail. They were of course assisted by other criminal/corrupt experts (LOL) of safety at sea saying that the Master of any ship is responsible for everything in spite of the ship being in perfect condition, bla, bla, bla. These experts were paid to lie. Media support them. My business is safety at sea. I have to live with these criminal experts and media since many years. They invent anything to protect criminals and to send innocent seafarers to jail. It is not fun. Safety at sea should be fun! 23 July, 2014, a year late, the water filled, worthless ship was lifted/removed off the rocks using external sponsons and a little later towed/removed full of water to Genoa for recycling paid for by insurances as removal costs. Why a worthless ship full of water was going to be recycled was not discussed. Actually no discussion was possible anytime! All was at the time the fault of the Master. 27 July, 2014 the ship with sponsons attached arrived at the Genoa Voltri container port and could be considered salvaged ... even if the value was negative. Plenty people wondered, why the worthless ship was not sunk again at deep water during the towage to avoid costly recycling. Was it because of the cocaine (see below) aboard? 22 January 2017 we still do not know! July 2014 the complete ship would be recycled by August 2016, it was announced. 1 August 2016 90% of the damaged hull of the ship was still below and full of contaminated water, only 80% of the deckhouse had been removed and nobody knew, when the project to recycle the ship would be completed or, if the hull could be provided with buoyancy, and float by itself ... ever. However ... 25 August 2016 buoyancy of the damaged hull of the ship was suddenly re-established, so it could float by itself without sponsons in order to be transferred to drydock. How? Easy! The complete

#0 bulkhead

deck of the

ship had been

reinforced and made

airtight, so that the

hull below could be filled by

compressed air to push out

17.000

tons of contaminated water in the

ship hull compartments.

There remained

~62.000

tons of dirty water. The water was

pushed out through damage openings in the

hull bottom below water, so the

ship floated on the

compressed air between water in the

hull and the airtight,

reinforced #0 bulkhead deck above.

You should wonder why the public was not

informed about this method a little

earlier. 1 September 2016

the transfer through the port of Genoa to

drydock of the ship

floating on compressed air took

place. The Port

of Genoa Port

Authority

did not provide any risk assessment of

this first-off operation. The damaged

ship hull could have

broken apart! The ship

had draught ~11.36 meters, when put

in the drydock 1 September

2016: 'When entering the drydock we had only around a 40-centimetre gap on each side of the ship and beneath it, in addition to limited visibility due to the ship size and the vessels involved in the towing operations,' said Gatti, adding that alignment manoeuvres were supported by laser measuring devices. So the limited visibility operation (?) was completed at 6 p.m. on 1 September 2016? Why not? But the water was not pumped out then. What happened to the water is not clear. I assume the bottom of the hull was still below water, i.e. the drydock was still half full of water.

Concordia (ex Costa Concordia) towed to drydock 1 September 2016 for final recycling. The ship floats on compressed air injected below a reinforced and airtight #0 main deck. The draught is 11.36 meters. The freeboard is only 0.02 meter So when the ship was put in drydock, 11.36 meters of it was still below water! The total displacement of it was about 79.000 m3 and with a ship lightship weight of still 17 000 tons, you needed about 17 000 m3 (or a little less) of compressed air below deck #0 to keep her floating. If they had put more compressed air into the ship, it would have floated higher at less draught. In drydock the compressed air was released and the ship landed on he drydock floor. Port of Genoa drydock 4 "has berthing distance of 267 meters (876 feet) with alongside depth of 11.4 meters (37.4 feet) and can accommodate ships to 100 thousand DWT." OK - so a water filled ship with displacement of say 17 000 (ship) + 62 000 (water inside) tons is put in it. The drydock is 40 meters wide, i.e. it has volume 121 752+ m3. The ship has beam 35 meters. So it is 2.5 meters free space between ship and drydock sides. Normally there are about 2 meters tall blocks in the drydock on which you put the ship in order to access the bottom for cleaning and painting and emptying tanks. Here there were no blocks! They were removed: The ship was put straight on the drydock floor, when the compressed air was vented. How any serious scrapping could be done is not clear. The ship in drydock has about 23.000 m2 of floor areas on three levels - A, B and C decks below #0 bulkhead deck - full of cabins, rotten stores, engines, pumps, dirty fuel tanks, etc, etc, with no light and ventilation. Someone must clean this big dark space and install lighting after 56 months below water. It is a stinking, slippery and dirty mess before it gets dry. Then there were 14.000 m3 of 40-50 double bottoms tanks to empty. And now the ship was recycled in a narrow drydock. It was a joke! Jokes like that are never reported in Italian and international media, even if I tell them. Holes in the side should of course be cut to facilitate ventilation. Light should also be installed. When the drydock is dry ... and not half full of water. Big holes in the decks will also be cut to lift pieces of scrap straight up and put them beside the dry dock, even if there is not much space there too. Recycling ships in dry dock - half full of water - is not a fantastic idea. It is pure stupidity. But media could not inform the public about it. Of course the public does not give a damn any longer about this shit put in a Genoa drydock. So you have to read about it here. 25 January 2017 I Googled "costa concordia dry dock genoa january 2017" to find out developments. The result was no pictures and nothing about the ship in dry dock at all. Twelve weeks of silence! Only links to me! So

they couldn't pump out the polluted

water into the port and pump the

drydock empty. What a

surprise! Furthermore,

the complete, dark (no lights)

inside of the ship

hull - double bottom tanks, tank

top, three decks with crew cabins and

service spaces, several engine rooms,

etc, etc - was full of and covered by

slime, shit, oil, grease, explosive

gases (?), rotten food and stores and

had to be cleaned and ventilated before

being accessed by workers to remove

furniture, carpets, wall and ceiling

panels of the >500 crew cabins, etc,

etc. How

to do it? Better to leave the water

where it is! That

question should have been raised many

years earlier but then the main

objective was to put the Master in

jail, so it was

forgotten. By

5

December

2016

there

were no pictures available of neither

the outside, nor the inside of

the ship in drydock. Imagine

that! Almost five years after an

incident at sea media cannot provide

any pictures of it. The

drydock was not dry - the contaminated

water was not gone - the outside

flat bottom could not be seen and

the inside could not be entered.

Maybe you needed breathing apparatus or

a diving suit to enter the bottom of

the hull of the ship?

Media,

as usual, did not report anything, even

if it was a great story, and the

Consortium

responsible

for the recycling was silent

until 24 December. Maybe nobody

wants to or is capable to clean up the

mess? It was just getting

worse. On

the other hand it was easy to cut/lift

off and recycle the

superstructure that was still

above water and above

deck #0 before deciding what to do

with the rest, i.e. a 290 m long, 35.5

m wide and 11.38 m deep hull

below deck #0. It

was only about 80.000

m3

of space on three levels - A, B and C

decks, i.e. about 23 000

m2

floor area, with no light and

ventilation to be lit up, cleaned out

and recycled after 56 months below

water. There lived once >1 000

underpaid, mostly Asian crew and

staff/slaves in >500 cabins, when

the unsafe ship was still floating. I

assume their personal belongings

are still there. Aft are the

engine/generators rooms, lub.oil tanks,

fuel pumps and piping of all kind and

the food/hotel store rooms. Forward are

dirty fuel tanks with hydrocarbon

gases, FW tanks and the laundry, etc,

etc. It

must be extraordinary spaces

just to enter into ... when they are

dry and ventilated and lit

up.

Media

should

ask for permission to document it. Then

they could also record and describe the

25

illegal watertight

doors

...

that caused the second

incident. It

appears that

by

September

2016

about

28 000 tons of steel, fittings and

waste had been removed from the deck

house above deck #3 and it has

taken about 30 months. If 17 000 tons

of steel, engines, motors, pumps,

fittings, wall and ceiling panels,

floor coverings, ducts, pipes,

furniture, electric cables, personal

belongings and waste remained to be

removed, separated and sorted from the

hull below at a rate of 200

tons/month (6-7 tons/day) another 85

(!) months were required. It meant that

the recycling may be completed say

Christmas 2023. In

the meantime Italian mafia

authorities established,

based on an Italian law of 1942 (!),

that it is a crime to accidentally

contact a rock below Italian waters

with a ship 2012, that it is another

crime to try help people abandon a

ship, even if the systems didn't work

due to ship owner's negligence, that a

third crime is not to prevent the ship

to capsize and sink, when underpaid

crew opened illegal watertight doors to

get out allowing water to spread, that

when these crimes were committed people

aboard were killed by the

Master, etc, etc,

bla, bla, bla. Being

a Master of a ship

is criminal in Italy! And amazingly, no

other Italian masters complained about

the treatment of one of their

colleagues! And the staff ashore

running the ships?

Silence! If any

cruise line office salary person

complains in Italy, he/she better

thinks first. Because ...

the

Italian mafia

authorities that apparently

runs the cruise business established

that everything at sea was criminal and

that the Master

alone was responsible for

everything and should spend 16+ years

in jail when something goes wrong! The

foreign ship owner of the ship? Not

responsible for anything.

Italian

authorities of all kind?

Sorry. Not responsible for anything. If

you are among >3 000 passengers on

an Italian flag ship with almost 1 000

crew/staff (most underpaid foreigners!)

and anything goes wrong ... it is

always the fault of one

person. The

poor Master!

He

is a criminal! He has no friends ashore

at Italy and in his

office. The

only solution is that he is put in

jail. Schettino

has 100's of

Italian

colleagues, Masters; Officers of all

grades on similar cruise ships of

different flags and also friends

ashore. But ... nobody gives a damn

about Schettino

since four years and ten

months. Or

safety at sea. My

business. Isn't

it sad? I

anders.bjorkman@wanadoo.fr

wonder.

Tell me! Thursday 30 March 2017 the ship in the drydock was still pretty impressive seen by Google Earth. The air tight main deck had been lifted off so you could see the tops of the main engines:  I assume there were

also plenty crew cabins, the wine cellar

and 25 watertight doors to

recycle. However late May

2017 I was informed that the recycling

was almost completed! In four months

17 000 tons of

ship had been cut to pieces

and removed somewhere and the drydock was

almost empty: Imagine that!

>140 tons/day of scrap of all

sorts have been cut off and lifted up and

away. It sounds magic! And the photo (from

a video on the Internet) doesn't look

real. It is fake! Anyway -

probably the ship hull

had been made watertight again in

drydock and ... one dark night ... the

dock was filled, the ship

floated at 5 meters draught ... and was

towed to sea ... and sunk! It took 30

minutes. I always wondered, if

real photos were made of the port side

shell damage and its length established

and if the condition of the 25 watertight

doors was established prior total

destruction or recycling or re-sinking! I

wondered also about the costs involved and

who has paid for the losses of it. This

case became stranger and stranger. Media

should really had investigated more. Maybe

my idea of a museum was not so bad after

all? My report below

explains in simple terms about (i) the

recycling at Genoa of the

wreck/ship originally owned by

Costa Crociere S.p.a, Genoa, Italy,

but sold or handed over to some Italian

interests at sea

26

July, 2014, for

scrapping that started

July

2014 - still

going on

2017

in a

drydock, (ii) the 30

months stay -

January

2012 - July 2014

- of the

ship on the rocks outside Isola

del Giglio and the risks of breaking

apart, (iii) the

September

2013 up

righting, (iv)

the

July 2014

liftoff

and refloating original and

modified operations of the seriously

damaged ship, so that 12 meters of

deck house full of stinking, rotten

shit became visible above water,

(v) the

towing from Isola del Giglio

to Genoa, (vi) the

(attempts of) replanting of corals on the

rocks outside Isola del Giglio -

and (vii) the

possible re-sinking of the M/S

Costa Concordia during the removal

towage. Yes, you read correctly

- re-sinking! But it did not take

place! It seems >200 interested

persons/day download this page early

2017! It is only 25 per day

2019 ... which is not

bad. I like it. But

media never quote me. For obvious

reasons. The recycling

work is evidently not done

according ISO

30000, Ship recycling management

systems,

that support environmental protection and

increase the safety of workers. You do not

recycle ships in a

drydock. If the recycling

work is done according to REGULATION

(EU) No 1257/2013 OF THE EUROPEAN

PARLIAMENT AND OF THE

COUNCIL of

20 November 2013 and amending

Regulation (EC) No 1013/2006 and

Directive 2009/16/EC is not

clear. Regulation (EU) No

1257/2013, also referred to as the

Ship Recycling Regulation

(SRR), entered into force on 30

December 2013. Article 7 of

said REGULATION rules: 1. A

ship-specific ship recycling

plan shall be developed prior

to any recycling of a

ship. The ship

recycling plan shall address

any ship-specific

considerations that are not

covered in the ship recycling

facility plan or that require

special procedures. 2. The ship recycling

plan shall: (a) be developed by the

operator of the ship recycling

facility in accordance with

the relevant provisions of the

Hong Kong Convention and

taking into account the

relevant IMO guidelines and

the ship-relevant information

provided by the ship owner in

accordance with Article

6(1)(a) so that its contents

are consistent with the

information contained in the

inventory of hazardous

materials; (b) clarify whether and

to what extent any preparatory

work, such as pre-treatment,

identification of

potential

hazards and

removal of

stores, is to take

place at a location other than

the ship recycling facility

identified in the ship

recycling plan. The ship

recycling plan should include

the location where the ship

will be placed during

recycling operations and a

concise plan for the arrival

and safe placement of the

specific ship to be

recycled; (c) include information

concerning the establishment,

maintenance and monitoring of

the

safe-for-entry

and safe-for-hot

work conditions for

the specific ship, taking into

account features such as its

structure, configuration and

previous cargo, and other

necessary information on how

the ship recycling plan is to

be implemented; (d) include information

on the type and amount of

hazardous

materials and of

waste to

be generated by the recycling

of the specific ship,

including the materials and

the waste identified in the

inventory of hazardous

materials, and on how they

will be managed and stored in

the ship recycling facility as

well as in subsequent

facilities; and (e) be prepared

separately, in principle, for

each ship recycling facility

involved where more than one

ship recycling facility is to

be used, and identify the

order of use and the

authorised activities that

will occur at those

facilities. 3. The ship recycling

plan shall be tacitly or

explicitly approved

by the competent

authority in

accordance with the

requirements of the state

where the ship recycling

facility is located, where

applicable. ... It would appear that

the recycling in drydock was

completely illegal and carried out by

unprofessional amateurs not on the

list

of EU approved ship

recycling

facilities!

Why the authorities assisted by

media do not stop the illegalities

is clear. It happened in Italy.

Nobody cares! Ever heard of the

Mafia? And the Italian

Master was anyway condemned to

spend 16 years in jail for the mess, so

the problem is solved. The whole job was

supposed to be completed August

2016 and here we were 2017

still cutting steel in drydock. And

no questions were asked! Below is a photo of the

ship full of water below waterline

a year earlier January 2016; no

later photos were available on the

Internet until end May 2017 - the

fake one above: In

order to recycle the complete

ship in drydock the top of the

damaged hull below deck #0 must

be above water, so the ship can float

on the hull, most steel above

deck #1 must be removed (the

ship/sponsons then float up

five, six meters) and then the damaged

hull must be emptied of water

and the sponsons removed. How it may be

done is described below. The

possibility that the ship breaks

into three parts is high! I am

surprised that the ship isn't

simply re-sunk outside the port to save

money. Maybe the cocaine (!) on deck #0

(superstructure!) must be found

first? How the ship arrived in

this sorry state is also described

below. The

wreck/ship Concordia +

sponsons at Genoa Voltri

July

2014

at 18.5 meter

draught The

ship of Costa Concordia

15

September

2013

just before parbuckling/up

righting. I

- photo left - made this web page

to help former Master of M/S

Costa Concordia - F.

Schettino - to win his appeal

against a 16+ years jail sentence

for having sunk the ship

14

January

2012.

The appeal was heard

April/May

2016

at Florence/Firenze (together

with other

appeals!)

and

31

May

2016

the court confirmed the previous

sentence ... according to some

Italian law from 1942! I

worked 20 years (1980-2000) with

Italian seamen, so I know many

Italian captains. When my friend

Francesco Schettino,

Master of M/S Costa

Concordia, contacted a rock

Friday 13 January 2012, I

felt sorry for him. |

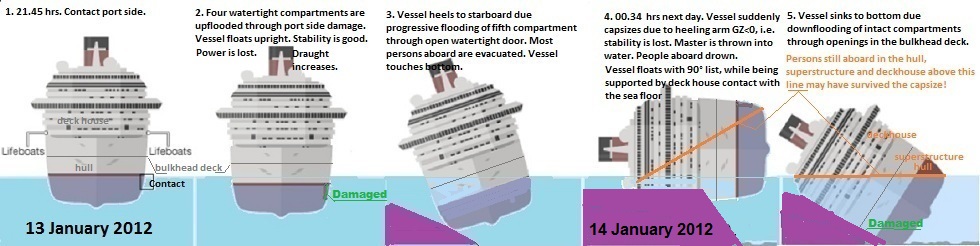

The generator rooms were flooded, there was a blackout that everyone noticed, i.e. no main electricity/light but the ship was otherwise floating, stable and safe with emergency light provided. Nobody died!

It was decided to abandon ship as per agreed company emergency procedures. A port was close by. The captain and some crew should stay behind to assist to tow the ship for repairs. But all lifeboats were not made ready by the crew! The responsible seamen were on vaccation at home! Very few liferafts were used. The available seamen didn't know how to launch them. Even worse! During the evacuation staff aboard opened (!) at least eight, illegal watertight doors #7, 8, 9, 10, 11, 12, 24 and 25 in the hull. They should have been kept closed or not have been there at all. Water spread, stability was lost, the ship capsized and sank Saturday 14 January 2012 and some people still aboard drowned. It would appear that the angle of heel was about 45° at 00.28 hrs (the ship was still floating), when the Master had reached the shore nearby and could witness the sinking from there. Schettino thus saved himself in the last moment. It was a total mess. The ship was not seaworthy!

The ship owner however, assisted by media, created a scape goat! The Master! It was all his fault! I describe it in the Introduction of this long report. An Italian court then sentenced Schettino to 16+ years in jail. Schettino appealed. It was an accident and he just followed company procedures. But the appeal court confirmed 31 May 2016 that the innocent but unlucky Master must spend 16+ years in jail. It is the cheapest way to solve the problems.

It is an Italian conspiracy. The ship was never seaworthy and insurances were not valid, which media will never report.

Below you can read about what happened and happens to the ship. It was still ... in drydock 2017 or what is left of it!

Actually no real ship refloating

was ever taken place. Only buoyancy in the shape of

sponsons was added to the ship at Isola del

Giglio, so it could be removed, still full of

water, to Genoa. The ship owner then

thought that the ship full of water had become a

ship again.

The

wreck/ship kept floating by sponsons

is November 2015 at a pier of the port of Genoa

being recycled, i.e. slowly being emptied of

outfitting and deckhouse is cut apart. When the

deckhouse structure is removed, the

hull may break into three

parts Many visitors are guided to this

page by various search engines, but you are

recommended to start reading the introduction and

summary of my Costa

Concordia article

because the whole show, not just the ship

removal and recycling show, is a scandal

that goes on and on. Or start reading about the

little Moldovan

dancer

and her role in the drama! 11 February

2015 the Master was

sentenced to 16 years 1 month in jail for, i.a.

sinking the ship and killing

people. The reasons were provided

10 July

2015 and can be

read here!

According to the verdict

"Thousands of cubic

meters per minute"* flooded some

damaged hull compartments

21.45 hrs

13 January 2012.

But nobody died then and the

ship didn't sink and no pollution was caused. The

Master thought the ship was safe and ordered

evacuation and abandonment as there was no

electricity, etc., available. Why the ship really

sank the next day has never been officially

established, but is explained here,

i.e. due to progressive

flooding of

undamaged compartments through illegal

watertight doors. It has happened before many

times.

The stupid crew/staff opened watertight hull doors

during the evacuation causing

progressive flooding and the loss of

stability, capsize and sinking!

The ship was not built according to the international safety at sea rules, SOLAS. It was not seaworthy and not safe any time.

|

The ship was never seaworthy and safe with American ship owner's and Italian authorities full knowledge.

The seven incidents - (1) contact, (2) confused mustering, (3) lifesaving appliances (LSA) not being made ready, (4) opening of illegal watertight doors, (5) confused embarkation into LSA, (6) capsize and (7) sinking - were just bound to happen, like they will happen again to many similar ships as safety at sea is getting worse all the time, like this one 2 November 2014.

On 21 September 2015, the prosecutors presented an appeal against the 16-years prison term handed to former Costa Concordia captain Francesco Schettino in February for the 2012 disaster off Giglio Island in which 32 people died. The prosecutors believe that the punishment is insufficient for the disaster, in which the Costa Concordia capsized three hours after sailing too close to Giglio and hitting a rock. They asked for a 26-years term at the first-instance trial, when Schettino was convicted of multiple manslaughter, causing a shipwreck, abandoning ship and abandoning incapable persons still aboard. But evidently Schettino didn't capsize the ship! The ship was incorrectly designed, not seaworthy and couldn't survive a small contact damage. And then Schettino just ordered his crew to evacuate all passengers/staff aboard according to the plans developed by the ship owner and approved by the Italian authorities ... which nobody had ever tested ... or trained for.

So Schettino also, September 2015, appealed against the ridiculous sentence. He wanted to be declared not guilty of seven incidents. It was one accident ... The appeal case was completed 31 May 2016 at Florence. The appeal court decided that Schettino was responsible for everything and shall spend 16+ years in jail.

The show thus goes on ... and on. But here only the 2012/2014 ship removal from the rocks outside Isola del Giglio and the 2014/2023 attempts of scrapping/recycling at Genoa is discussed. It is a show in itself, the ending of which that media will not report. You have to read about it here.

Genoa

is not a place to scrap ships. Ships are

scrapped and recycled at Bangladesh, India,

Pakistan and in similar poor and developing

countries. The old ships are run up on beach

there and cut into pieces that are sorted and

recycled. It is done relatively safely, while

protecting the workers and the environment

nowadays according to new rules being developed.

I have assisted sending >20 ferries or ships

to these countries the past ten years and many

more since 1980. Italy has

however announced it can be done better and

cheaper (?) at, e.g. Genoa, and that the

Costa Concordia ship will start a new

ship scrapping industry there. It is

evidently 100% nonsense. It is a joke! Part

of a fraud to get money from underwriters and to

cover up a crime. Since

Concordia arrived at Genoa July

2014 no other ship or wreck is lined up for

scrapping at Genoa or Italy! There is no

infrastructure for it in Genoa. The whole thing

is a criminal event to continue stealing money

from insurances and the Italian government

assisted by media. So media cannot report

what happens. You have to find out about here!

If you try the links below to the

Consortium

recycling the ship, you'll find that on July

27, 2016: It seems they

are far behind any schedule. I am curious to see

what happens next. I fear the ship

will break into three parts in the port and all

three parts will later be sunk outside the port.

Concordia

dismantling and recycling operations are

progressing and the about 200 technicians are

working on the ship and cutting decks –

from 3 to 1 – while the decks from 14 to

3 (partly) have already been

removed.

The sections in chapter 11 of this report are numbered #1-54 here for easy reference. There are many interesting aspects of the removal including scrapping/recycling of the wreck/ship never reported by media. I hope you will find them interesting and entertaining, even if it takes time to study them. The sections are:

1. The Concordia wreck/ship is back at Genoa July 2014 at 18.5 meter draught - how did it arrive there and why is it a tourist attraction. Will the wreck/ship finally break into three parts? Four phases of dismantling/recycling. Project delayed several yearsPhase 1: Stripping - the easy part - part completed 15 May 2015

Phase 2: Towage to the "Molo Ex Superbacino" jetty, dismantling of the steel deckhouse decks #2-14 and transfer of sponsons control equipment - a feasible part - but when will it be completed? This phase was completed August 2016

Phase 3: Making the damaged wreck hull watertight enabling removal of 30 sponsons and towage to dry dock - a very complicated and difficult phase and probably impossible to do. This phase was also completed August 2016

Phase 4: Final dismantling in dry dock going on since September 2016. Alternative is to tow the ship out to sea and re-sink it

2. Definitions

3. Background - no answers 14 April 2014 - just stupid excuses

4. Re-sinking

5. Preparations for liftoff

6. The situation is under full control - competent Italian authorities check everything including the sophisticated automatic system

7. The tall bow and stern sponsons

8. Liftoff

9. Refloating ... may go very fast ... and is a very dangerous business

10. The towage - and further risks of breaking apart - answers 16 June ... sorry 25 or 26 June!

11. What really happened 14 - 23 July 2014

12. About the possibility that the damaged ship would remain at Isola del Giglio 2015

13. "Maritime Casualty Response award" presented to the Salvors

14. Some people believe the Costa Concordia removal job is already done

15. The capsized and sunken ship 14 January 2012 - 16 September 2013

16. The support of the submerged but up right ship 17 September 2013

17. Will the ship really be refloated June 2014? And will it cost another ¬ 300 million to scrap it? Where, how, is it possible?

18. Costa Concordia Could Be Towed To A British Port - Decision end March 2014

19. The refloated ship will remain in Italy

20. The magic removal show 2012-2014

21. Up righting of the ship 16 September 2013 - further structural damages to the hull

22. Why are there no reports about what happened to the hull under water?

23. A simpler, safer, less expensive and more ecologically friendly removal method was not chosen

24. The wreck/ship owner selected the Salvors April/May 2012

25. A complicated, time consuming, untested and expensive removal method was chosen

26. "The work to remove the ship in one piece by refloating and towing it away from the site will take 12 months"

27. Parbuckling structurally damaging the ship and compressing the sea floor

28. Parbuckling

29. The ship has sunk 3 more meters since capsize

30. The difficulties to parbuckle a delicate hull structure on an uneven, rocky sea floor

31. The parbuckling took place 16 September, 2013

32. Thanks

33. No documentation of the damaged hull underwater made available before and after parbuckling

34. Can the damaged ship actually liftoff from the bottom and be refloated and towed away?

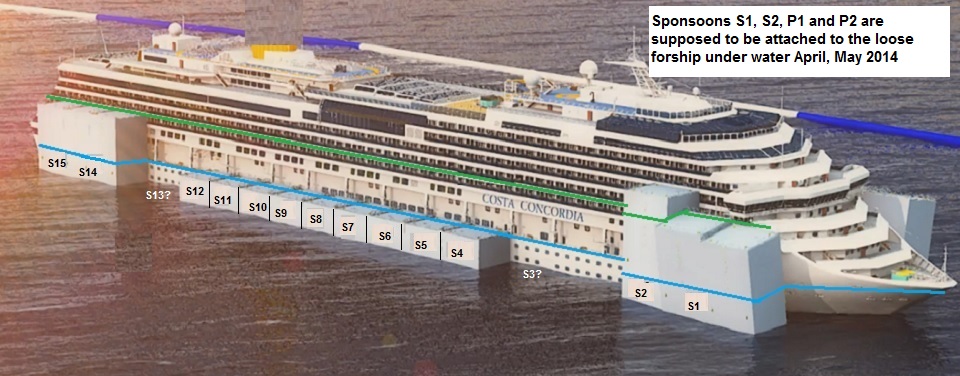

35. ... underwater attachment of 4 port and 15 starboard sponson tanks spring 2014 and other works to secure the upright ship

36. What happens end June 2014

37. Rudders removed - a diver dies

38. Activities 15-21 February 2014 at the ship

39. The bumper

40. The big liftoff and refloating show - final difficulties, risks and surprises to consider at this stage

41. When the ship lifts off at 29.99 meters draught ... will it drift away ... or break apart?

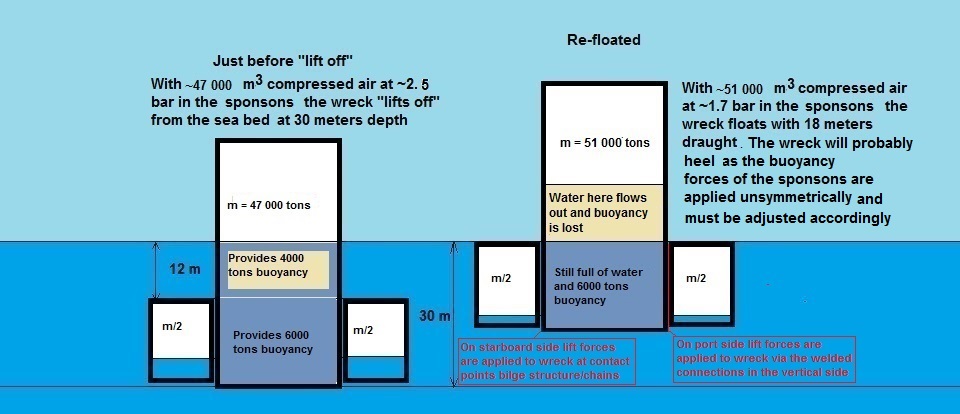

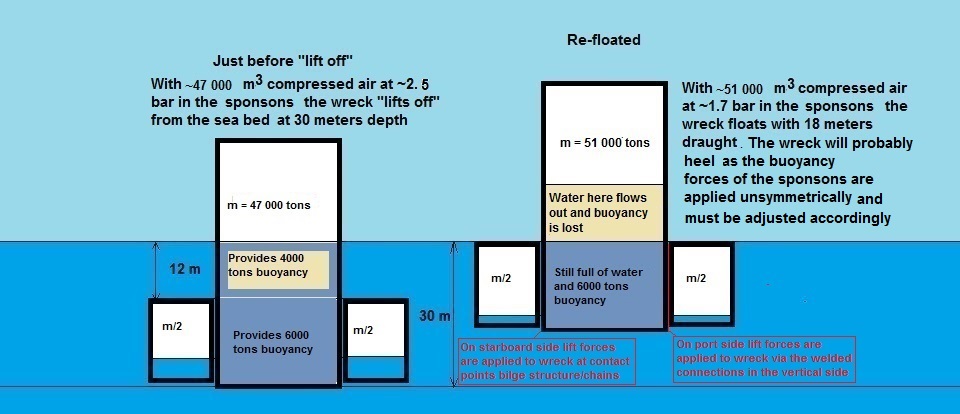

42. - 47 000 m3 buoyancy for liftoff

43. The ship sags and hogs ... under water

44. Only 4 000 m3 of extra buoyancy required to raise the ship to 18 meters draught after liftoff

45. Removal of the starboard stabilizer fin

46. Nick believes the ship will rise 22 meters and float at 8 meters draught

47. Towage starts - where to?

48. The Dockwise Vanguard solution to transport away the refloated but still damaged ship

49. Why wasn't the port side hull repaired and the starboard side bilge reinforced prior up righting?

50. The simpler, less costly method to refloat the up righted ship

51. Staggering costs

52. Optimistic officials - September 2013 - No cure, no pay

53. Re-planting corals 2016!

54. Alternative solutions and no examination of the ship!

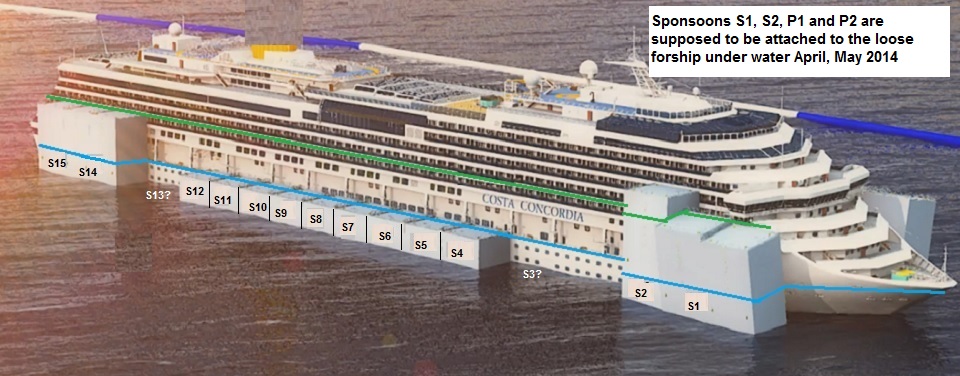

1. The Concordia wreck/ship was back at Genoa July 2014 at 18.5 meter draught - how did it arrive there and why is it a tourist attraction. Will the wreck/ship finally break into three parts? Will the illegal drugs be found? Four phases of dismantling/recycling. Project delayed several years

The wreck/ship Concordia was neither safe nor "seaworthy" when it arrived at Genoa July 2014 - it could sink at any moment!

It was reported that the Costa Concordia wreck/ship full of water was sold (sic) at sea 26 July 2014 at unknown price and conditions or simply handed over to a Consortium of Saipem (Italian government oil (!) company)/San Giorgio del Porto (small local company with no experience of ship recycling (!)), but who buys a waterfilled wreck/ship at sea kept floating by sponsons that can sink any time? Maybe the ship still belongs to the ship owner? We do not know. The value of the ship is also negative as the cost to scrap the ship in an environmentally friendly way is said to be €100 million. Did ship owner Costa (or insurance) pay the Consortium €100 million to get rid of it? Nobody knows! Media is not interested. Why would this strange Consortium buy this wreck/ship? The name of the ship was shortened to Concordia, even if another name was still seen on the bow. Anyway, the Consortium maintains they own the ship 2016.

Maybe the unsafe wreck/ship was

not permitted to enter the port unless it was formally owned

or controlled some way by the government/local interests?

The draught was 18.5 meter.

On 27 July 2014 the

ship with sponsons attached

nevertheless arrived at the Genoa Voltri

container port and moored in a corner behind a

jetty. It could still sink there again! Reason is

that the water filled wreck/ship is floating

assisted only by the sponsons relying on

compressed air supplied by compressors at the top

of the sponson to push out the water through an

opening hopefully with a valve in the bottom. If a

valve of the sponson leaks and the

compressed air escapes and water enters the

sponson, the wreck/ship will

sink. It would have been much better

and safer to use watertight

pontoons.

Media,

which have not covered the incidents properly since

January 2012, reported more nonsense as usual,

e.g:

"The ship (sic) was moored at a port in Genoa last month after the biggest maritime salvage (sic) operation in history."

Actually no ship was salvaged. A water filled ship of no or negative value had only been removed from one place to another and we haven't seen the end of the show yet. I wonder why media always report incorrectly. Do media believe that a ship will sail away like the Flying Dutchman? Haven't media understood that the hull, superstructure and some parts of the deckhouse of the ship are full of dirty water? Ships are never full of water and their bilges are always dry. Ships float on water! This stranded ship is only kept floating by sponsons port and starboard.

In the meantime the wreck/ship Concordia became a tourist attraction at Genoa to be looked at from the outside. It could not be totally scrapped at its original, temporary, unsafe location at Genoa Voltri, so it was possible to tow it out to sea and sink it again? Re-sinking! To save money. I explain how below. It never took place in May 2015, though.

Antonio Benvenuti, the head of Genoa's harbour workers' union, told AP (July 2014) that there was no "precise schedule" for each stage of dealing with the wreck or ship. Only in January 2015 some info was provided. But who cares? Insurances? They pay gladly and are part of the conspiracy and fraud.

As Antonio Di Pietro has said and demonstrated several times: it is a fact that Italy is corrupt to the core and it costs very little to arrange anything by just paying the right people. Genoa is just part of that scene. What was seen 2014 at Genoa Voltri port and what will be seen 2015 and 2016 at Genoa are just the latest acts of the Costa Crociere S.p.a, Genoa, Italy, Costa Concordia show.

The Genoa port authority on 18 October 2014 declared that the water filled wreck/ship (mass 45 000 tons) and empty sponsons, (mass about 15 000 tons) kept floating by sponsons at 18.5 meter draught were "safe" and that demolition could start by emptying the humid, cold, slippery deckhouse above water by removing say ~15.000 tons of furniture and fittings (it is a lot!) in it at the present location. Later only 5 700 tons were removed. A little crane was already installed at Isola del Giglio in the swimming pool amidships for this big job that will take six (!) months apparently assisted by containers and barges. It is all fantasy of course, nobody cares about the Genoa port authority and media report the nonsense and then do nothing. Recycling a wreck/ship full of water! It is a joke. So hereafter I regard the wreck/ship as a ship!

The total mass of ship (45 000 tons of scrap) and sponsons (15 000 tons) at say 18.5 meter draught is about 60 000 tons. The submerged parts of the water filled ship provides about 9 000 tons of buoyancy, while the submerged parts of the empty sponsons provide 51 000 tons of buoyancy. By removing 15 000 tons of material from the deckhouse ship above water, the ship with mass about 45 000 tons floats up to a new equilibrium at say 13.5 meters draught, where the submerged parts of the ship provide about 7 000 tons of buoyancy and the submerged but empty sponsons 38 000 tons of buoyancy. Or something like it. I haven't got the hydrostatic data of the ship + sponsons. It is not easy to reduce the draught of a water filled ship by removing weights (mass) from the top, though.

There is about 24 100 tons of various waste; bulk* (e.g. tables, chairs, sofas, mattresses etc.), wood+ (e.g. doors, shelves), glass*, plastic,+ paper and cardboard+, waste from electrical/electronic appliances+ (e.g. TV sets, fridges, lamps), packaged products* (e.g. soap, detergents, packaged food products), scrap metal+(say 4 100 tons), insulation*, fittings+ (e.g. tiles, shelves, marble) to remove from the ship and to transport to Savona, Alessandria, Genoa, Milano, Torino, Pistoia and Alessa. About 10 200 tons will just be disposed* of and only 13 900 tons will be recycled+. The rest - 20 900 tons - is steel plates, steel pipes and steel engine parts and similar that are easy to recycle ... somewhere. It is reasonable to assume that there is about 25.000 tons of steel to recycle (55% of the total light ship weight) and if you can sell it for €250:-/ton then you make €6.25 million. Therefore the total €100 million project seems to be a complete loss maker from the start. So why the interest to recycle the ship?

There is also a big shipment of Italian mafia drugs hidden aboard! Among the packaged products! On deck #0 in the superstructure. Still four meters below water 1 May 2015! I would have expected that the drugs were brought ashore at Isola del Giglio and delivered to a yacht in the port in cover of the big confusion 14 January 2012 but it seems not correct. The Mafia says they lost the drugs. The drugs may be the reason for bringing the ship to Genoa for recycling.

Because since 26 March 2015 the ship is under 24/24 watch. The drugs are still aboard! Media does not really write about it. Italian police is not interested!

The mafia drug connection was already mentioned 2 March 2012, more than three years ago, but nobody bothered about it. It was suggested that a bag of cocaine was going to be dropped off outside Isola del Giglio by M/S Costa Concordia to be picked up by a yacht in the port and that the Master (and mistress?) was/were going to be paid another bag of money, etc, etc. It seems things went wrong, the planned turn/drop off was sabotaged, steering gear and VDR disconnected (??), and the ship contacted a rock close to shore as described in the first part of this report. The cocaine was never dropped off! It was still 2015 inside what is today a ship at Genoa.

Maybe the mafia will recycle its plastic protected cocaine there now? But beware - the ship with everything in it belongs to the ship owner Costa! Unless it belongs to the scrapping Consortium. Nobody knows anything 2017!

Could anybody really remove 100

tons/day of waste from the top of a ship

kept floating by sponsons? The hull of the

ship is full of dirty water and moored in a remote,

exposed location subject to wind and rain - like a deserted

island. The location is not suitable as a scrap yard. Who is

paying for this comedy? What kind of Italian workers will

accept to work there and under what conditions? Are they

"safe"? How many are they and what are they paid?

Is the ship insured? What happens if anything

goes wrong? And can Italian demolition workers' safety and

welfare be assured? Has Italian labour authorities approved

the work site as "safe"? Are there toilets and rest

rooms available? Etc. It seems some workers sell

pieces of the ship as souvenirs to make ends

meet. I doubted very much that

15.000

tons of worthless furniture (old beds,

mattresses, chairs, tables, TV-sets, etc.) and

fittings (bathrooms, wall and ceiling panels,

carpets, doors, windows, electric cables, etc.) can

be cut off, moved 100's of meters to containers

below the crane and then loaded on barges to be

transported ashore to another location in the Genoa

Voltri container port - for sorting and

recycling! - in six months (it will take

much longer). Of course some work has apparently

started - 220 persons are reportedly at work

on decks #4, 5, 6 and 7 - but we do not know how

long it will last. On 4 March 2015 only

deck

#6 was fully cleaned

out. We thus had to await

developments.

The Consortium

of final removal and recycling of the ship

had other ideas (January 2015) shown in this

video

and described here.

It believes it has received a vessel and will scrap a

ship. But ships are not full of

water.

Photo Anders Björkman

There were four phases of the Concordia ship scrapping and final removal:

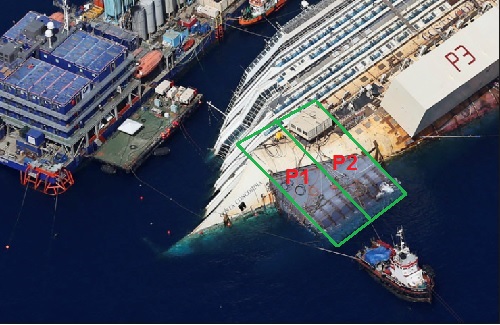

Phase 1: Stripping - the easy part - completed 15 May 2015

The first phase involved the stripping and removal of the furnishings, fittings, wall and ceiling panels, windows, doors, cables, pipes, ducts, i.e. the complete cabins/corridors/public rooms of the deckhouse above water. It is quite simple. No real hot work or cutting. The objective was to reduce the draft of the ship apparently to from 18.5 to 13.5 meter.

It was estimated that about

8.000

to

10.000

tons (not

15.000

tons) of waste material needed to be

removed. Phase 1 was expected to be

completed in the first few months of 2015 (possibly

March 2015). All different waste is

transported ashore and recycled by somebody

somewhere. On 1 May 2015 the draught

appeared (seen from a distance) to have been

reduced only one meter, i.e. from about 18.5

to 17.5 meters. At this rate the

stripping may be completed early 2016 ... or

later. On 6 May 2015 we were

told that only 5 700 tons of waste (cabin

outfit) had been removed (i.e. only 20

tons/day) and that the ship was going to

be moved to another jetty - phase 2 -

subject to approval by safety experts and the Genoa

port authority. On May 15 the

transfer

to the "Molo Ex Superbacino" jetty took

place. The draught of the ship was not reported. It

looked to be about 17 meters, i.e. the water

filled ship was still mostly below

water.

It appears that this phase was late.

Evidently 200 persons cannot remove 500

kg/day/person or 100 tons/day of waste like

that, so maybe during the summer we will see ...

about two decks full of rotten shit previously

submerged will float up above water. Who pays

how much is not known. The value of the waste is

zero.

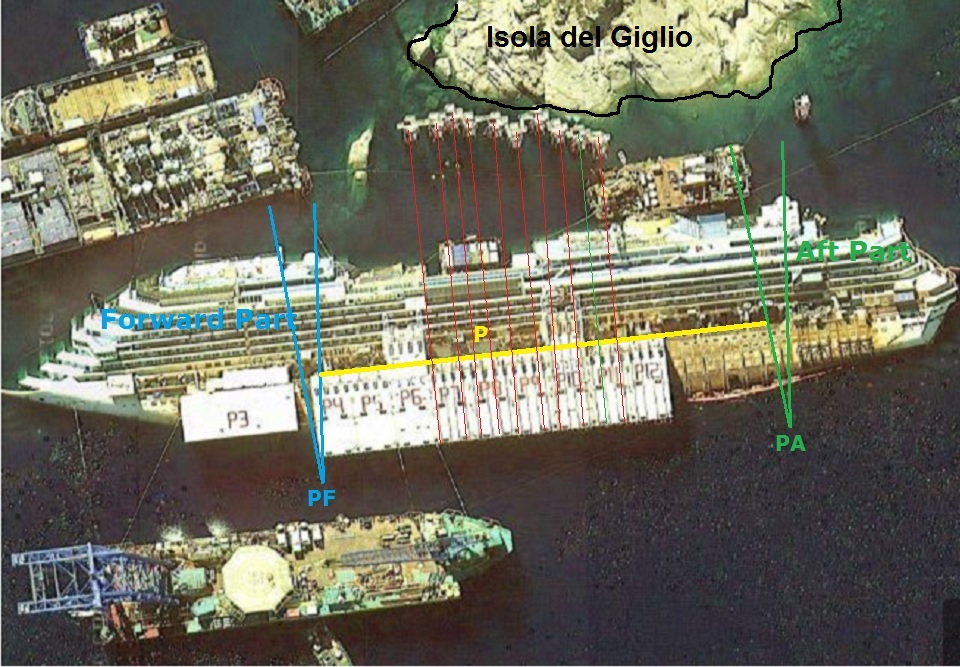

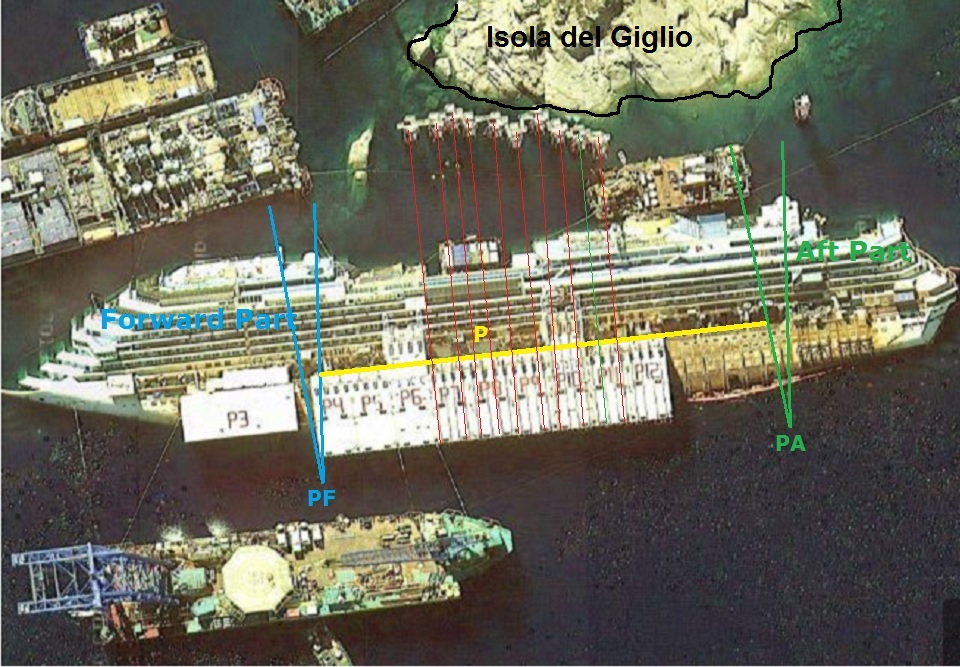

Phase 2:

Towage to the "Molo Ex Superbacino" jetty,

dismantling of the steel deckhouse decks

#2-14 and transfer of sponsons control equipment -

a rather simple part - but when will it be

completed? August 2016! Once the Concordia

ship reached a required draught (about

17 meters), it was 15 May 2015 towed to the

"Molo Ex Superbacino" jetty. The compressors and equipment to

control valves for the air in the sponsons

installed on top of the deckhouse are

transferred somewhere else. On 27 July 2015 the

company

informed that another 830 tonnes of material

had been removed (as of 30 June 2015) since

15 May 2015, or 550 tons/month or <20

tons/day. With this work speed it will take

>2 years to finish Phase 2. However the

company is optimistic: The majority of the material

(approx. 80%) was sent to recycling

facilities.

During the towage there was a great

opportunity to re-sink the

Concordia ship to avoid further work.

The Concordia ship could be sunk

beside the tanker ship M/T

Haven outside Genoa. As the drugs are on

#0 deck in the superstructure, they can probably

be recovered before re-sinking

using divers. However, the ship was not

re-sunk.

The Consortium thought that their (or Costa's)

wreck was a floating ship (sic). The

steel of the deckhouse (with mass say

30.000

tons steel and outfit) (decks,

bulkheads, walls, etc) shall now be cut - hot work

- into smaller parts and removed to the jetty for

disposal somewhere. As the deckhouse

contributes to the longitudinal strength of the

damaged ship, it may break apart during

these operations. Longitudinal bending moments and

shear forces applied must be kept minimum by

correctly adjusting buoyancy applied by the

sponsons (port (jetty) side attached by

welding, starboard (basin) side by

chains).

Can they remove 100 ton of steels/day, it will

take 300 days. If they remove 50 tons/day it

will take almost two years. The draught will

then be further reduced to say 9-10 meter and

two or three more decks submerged below water

will float up above water. The depth of the

hull/superstructure is about 14.5 meter.

Who pays how much is not known. The value of the

scrap steel is known but does not pay the costs.

How safety is maintained is not clear."The current deck demolition phase

will take another 6 months with work expected to

be completed by the end of

2015".

|

|

The "strip out" of outfitting was concentrated on decks #3, 4, 5 while work was commencing on deck #2. Deck #14 had been removed and work was now underway on the complete demolition of deck #12. The cutting operations entail slicing the steel plates into pieces small enough to be transported by road (maximum size approximately 2.2 m x 8 m) ... somewhere. There are at least 100 000 m² of thin steel deck plates to cut so we talk about at least 6 000 pieces about one ton each. No big deal really. Then there are other rubbish, pillars, stairwells, davits, trunks, etc, etc, maybe another 4 000 tons of steel. 21 September 2015, almost 14 months after arrival, only decks #11-14 had been removed and the draught appeared to be 15-16 meters. Six trucks were leaving daily with scrap of various types and if they actually remove 100 tons/day they may be ready for phase 3 in April 2016! We will see. I assume the cocaine will be found on deck #0 ... around Christmas 2015? So in order to be ready in December 2015 you had to increase the demolition to at least >60 tons/day. It seems (photo left) that big blocks of scrap steel were lifted off the ship by a floating crane (!) and transported across the port for further cutting into smaller parts at a flat area on a jetty. Very strange and costly way to scrap a ship! During the winter/spring 2016 decks #0-3 (various public rooms, kitchens and also store rooms) will finally rise above water. They must also be stripped out of outfittings before steel cutting can take place. |

At that time the the Master's appeal had been handed in to the appeal court at Florence (Firenze) since September 2015, so media will have something to ignore.

February 2016 the Phase 2 was nowhere close to be finished. Only 16 000 tons of steel/outfit (out of 30 000) had apparently been cut off and removed above deck #5 of the deckhouse. Deck #5 is the open mooring deck forward, which remains in place.

|

At present rate of cutting (60/70 tons/day) the remaining four decks of deckhouse and one deck of superstructure (say 14 000 tons) may be removed after 200 days say September 2016! But let's face it. If the only way to remove scrap is by a floating crane, you will never get finished. The existing cranes on Molo Ex Superbacino jetty seem too small to handle the demand. Deck #1 - the top of the superstructure - was however finally above water January 2016 but there was no news about the cocaine on main deck #0. Evidently the complete hull below deck #0 is still full of water and only kept floating by the sponsons. To proceed with Phase 3 the draught of the ship must be reduced removing decks #1-5 of the deckhouse and superstructure - so you can access the main #0 deck in order to clean it up, make it airtight and create buoyancy there before removing the sponsons. |

|

The Consortium has made reports about the progress of Phase 2 as follows:

STATUS UPDATE DECEMBER 23th 2015

December 28, 2015

Concordia dismantling and recycling operations are quickly progressing. About 200 technicians are now working on the wreck. Cutting has reached deck 5 while strip out operations continue to remove internal fitting with work about to be completed on deck 2 and beginning on deck 1. As the weight of the wreck becomes lighter, it is ...

STATUS UPDATE 16th FEBRUARY 2016

February 17, 2016

Concordia dismantling and recycling operations are quickly progressing and the deck 0 is about to re-emerge. About 200 technicians are now working on the wreck and cutting decks - from 5 to 3 - while strip out operations continue to remove internal fitting with work about to be completed on deck 2 and 1. As …

STATUS UPDATE 6TH April 2016

April 8, 2016

Concordia dismantling and recycling operations are quickly progressing and the deck 0 has re-emerged over the past weeks. About 200 technicians are now working on the wreck and cutting decks - from 5 to 3 - while strip out operations continue to remove internal fitting, with work about to be completed on deck 2 and ...

So, 200 technicians were December 2015 to May 2016 working or quickly progressing to remove the steel structure of decks #3-5 of the deck house and the outfit of decks #1-2 of the deck house, while the hull below deck #0 is still below water! And then there is the steel structure and outfit of deck #0 of the superstructure to dispose of, before you can access the hull below deck #0.

It would be interesting to see how the damaged hull below deck #0 that is full of dirty water will be cleaned out and how to restore autonomous buoyancy, whatever that is. Self-governing buoyancy? In order to restore autonomous buoyancy you must remove plenty sea water from the hull. But how? There was no news of the drugs on deck #0 either. I did not really wonder why media had lost interest in this scandal. Do you?

How the hull full of water was to be provided with buoyancy was not clear!

On July 27, 2016 the Consortium informed:

Concordia dismantling and recycling operations are progressing and the about 200 technicians are working on the wreck and cutting decks - from 3 to 1 - while the decks from 14 to 3 (partly) have already been removed.As the weight of the wreck becomes lighter, it has been possible to remove 21 sponsons so far, out of the 30 originally installed. Simultaneously operations are in progress to maintain the restored buoyancy to the hull so to allow to remove all the sponsons and then to transfer the wreck to dry dock where the final demolition will take place.

So maybe they have already started Phase 3? But is the waterfilled ship July 27, 2016 kept floating by only 8 side sponsons and the blister? If the draught is 14 meters 8 sponsons and the blister can only provide 13 000 m3 buoyancy. Maybe some double bottoms tanks have been pumped dry to provide buoyancy? Anyway, all sponsons must be removed in order to reduce beam at to proceed and the draught must be reduced to <12 meters to put the ship in drydock.

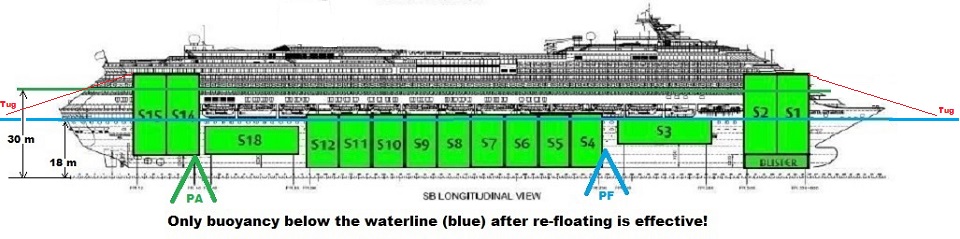

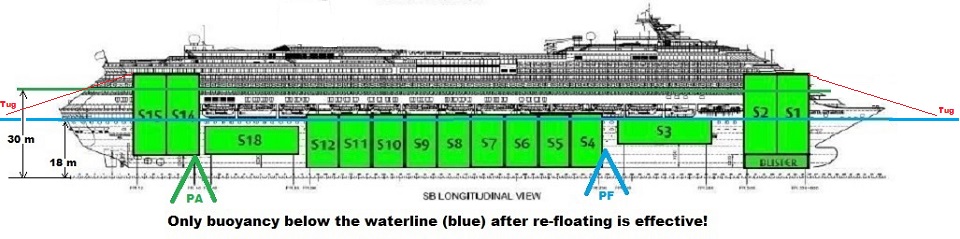

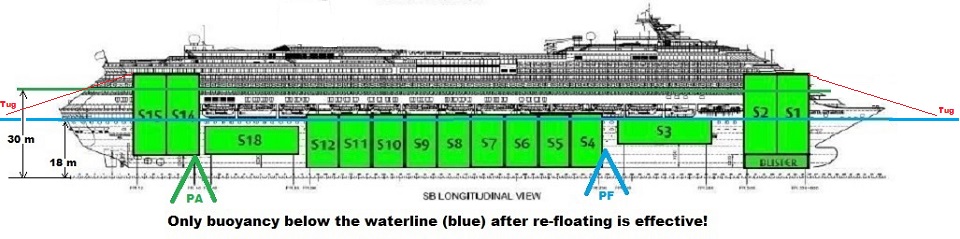

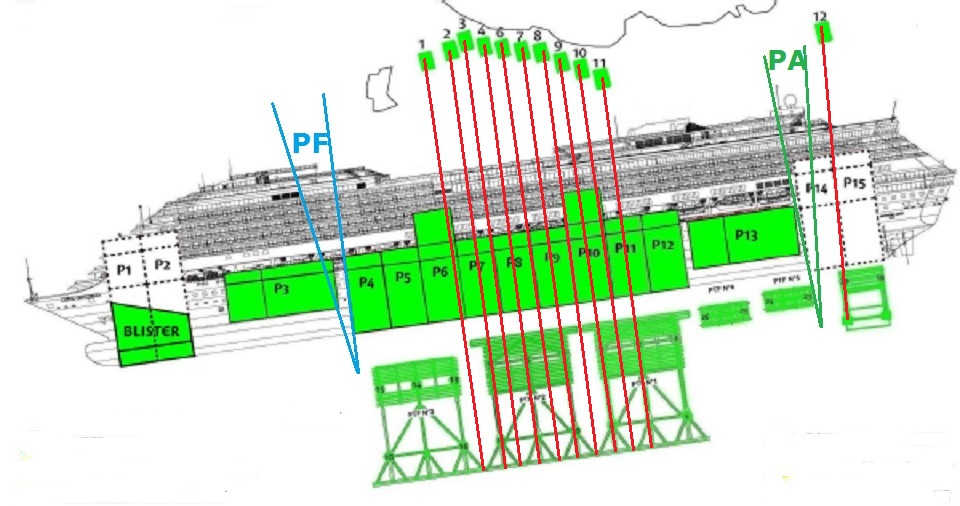

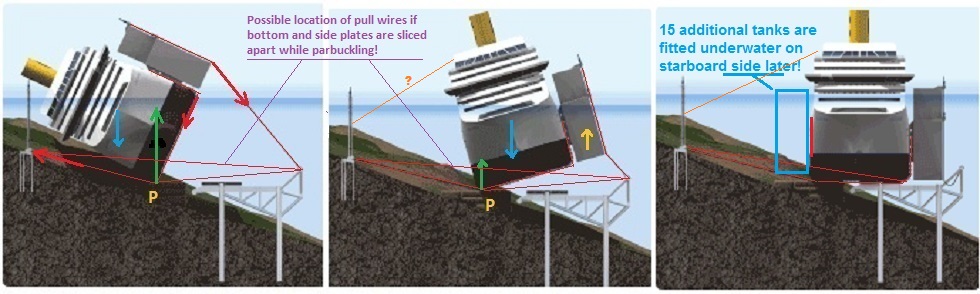

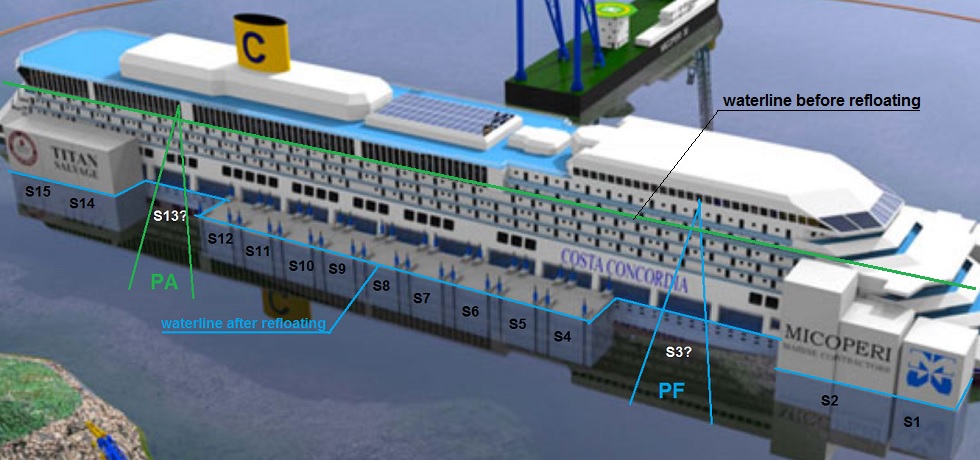

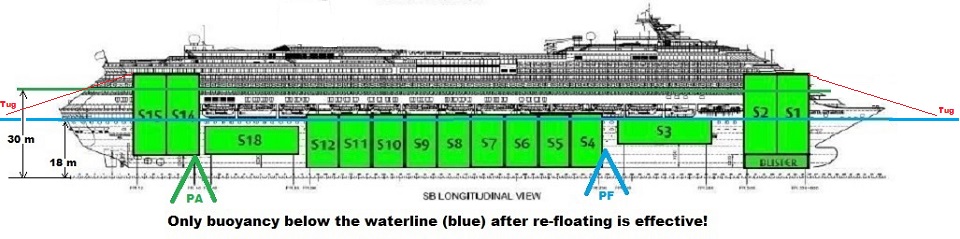

Phase 3: Making the damaged ship hull watertight enabling removal of 30 sponsons and towage to dry dock - a very complicated and difficult phase. Completed 30 August 2016

The hull/superstructure has beam

~35 meters and depth ~14 meters and is only kept floating by

30 10 meters wide sponsons attached port and

starboard. Total beam of the ship is

therefore 55 meters, which is too much for the

drydock at Genoa. After the deckhouse has

been removed, the draught may still be 8-9

meters. The hull below deck #0

has engine rooms and three decks (A, B and C)

with crew cabins, store and service rooms in many

separate compartments. The objective of Phase 3 was to

create, say ~17 000 m3

buoyancy inside the hull by making

several of the water filled ship

hull compartments below water

airtight at the #0 deck level. By

filling the spaces with ~17 000

m3 compressed air and pushing out

some

17.000

tons of dirty water to maintain draught of the

hull further to say 11 meters, the ship will

float again! There will still be

60.000

-

70.000

m3 of polluted water inside the

ship.

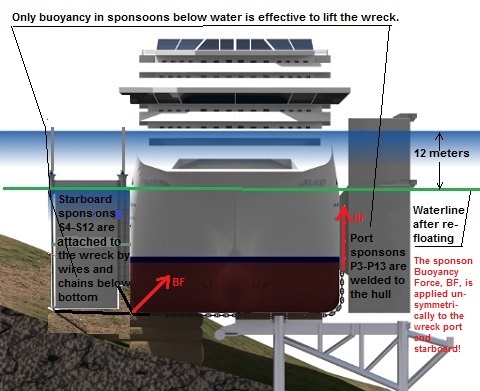

The Consortium said it was able to remove the 30

sponsons (boxes with mass say 15 000

tons - flat steel plates - also to be recycled but

somewhere else) and its, say

~10.000

m3 buoyancy, attached outside by

welding (port) and chains (starboard) as shown below before

towing the ship to dry dock no. 4, where final

dismantling of the hull will take place.

In principle it should be easy to provide inside and remove outside buoyancy, when the top of the hull - deck #0 - is above water. But you have to reinforce the #0 deck of the ship!

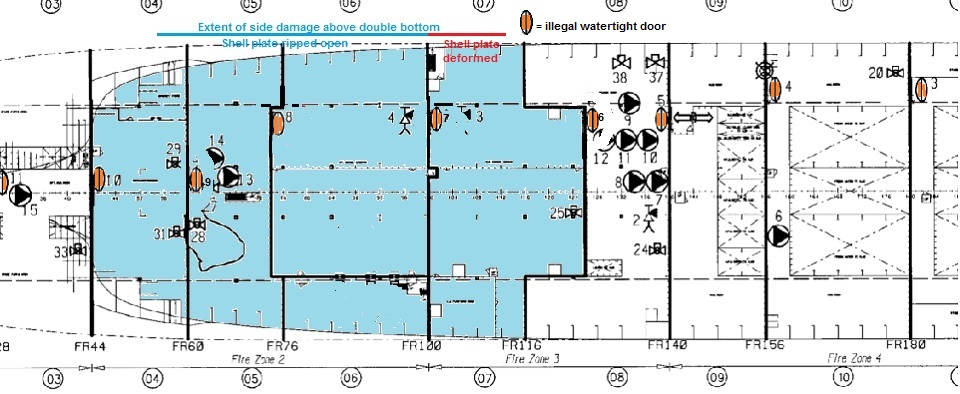

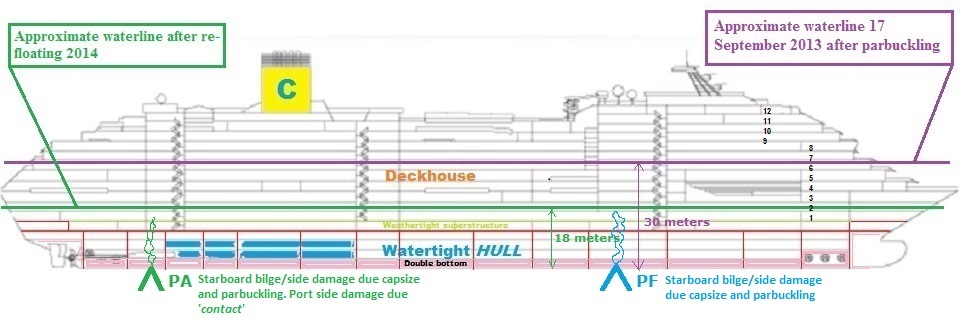

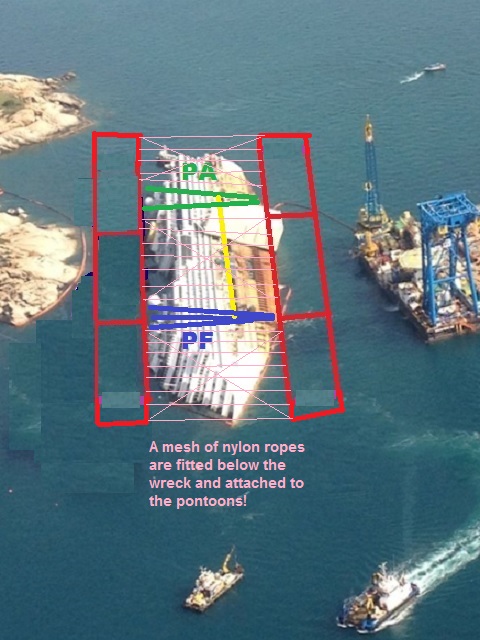

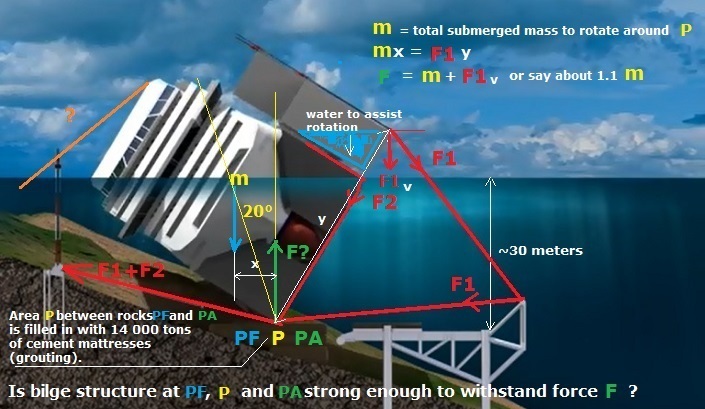

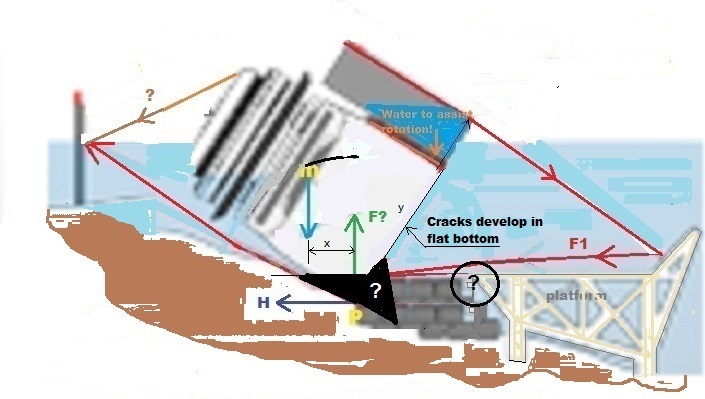

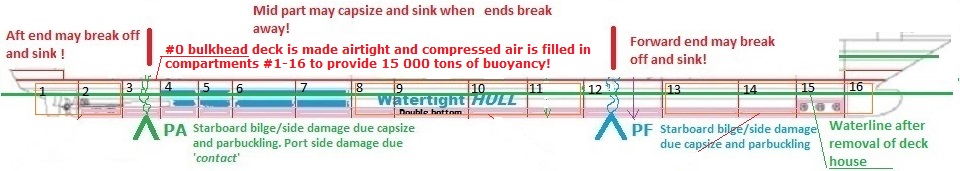

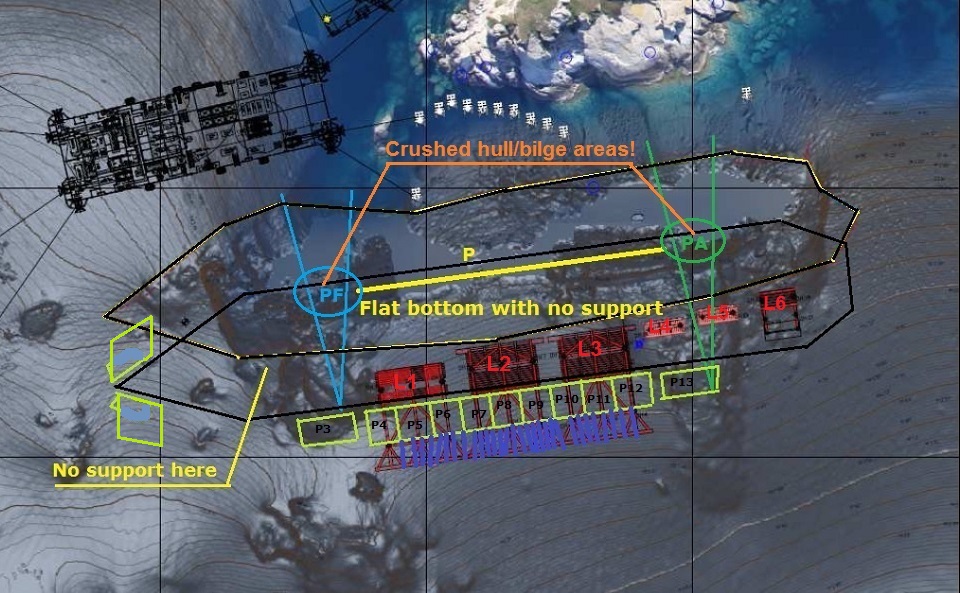

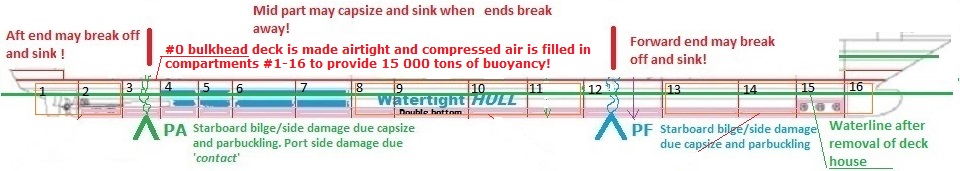

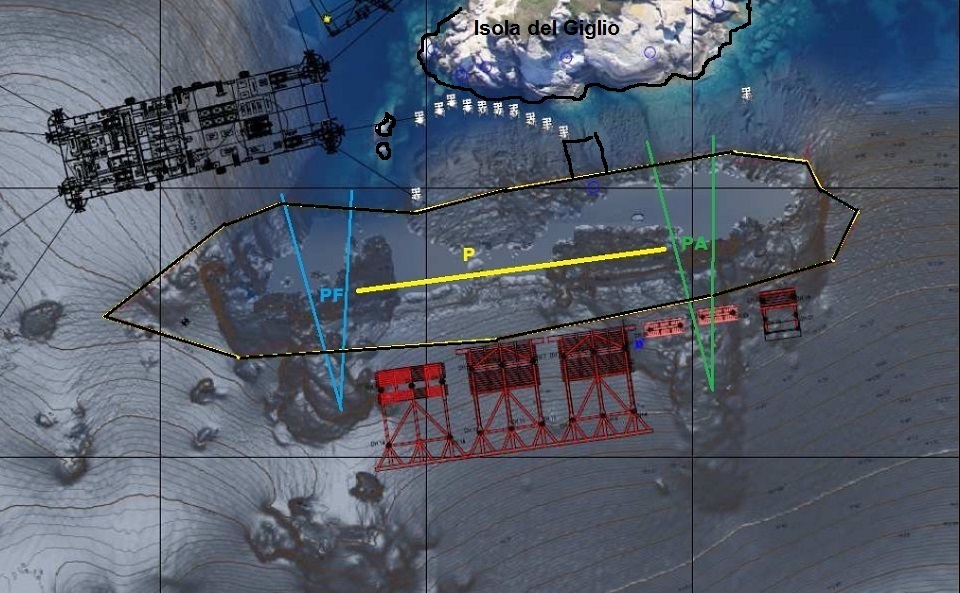

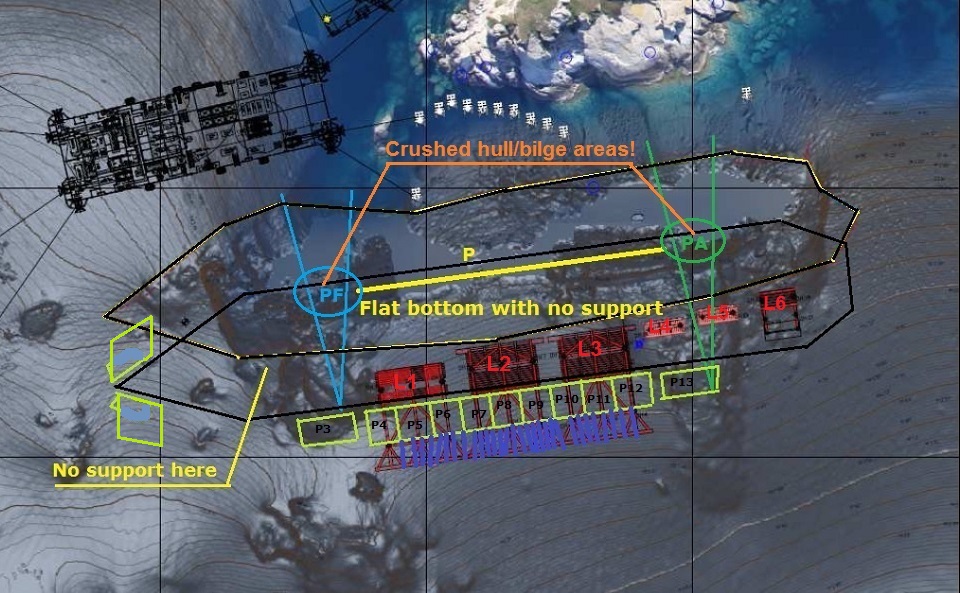

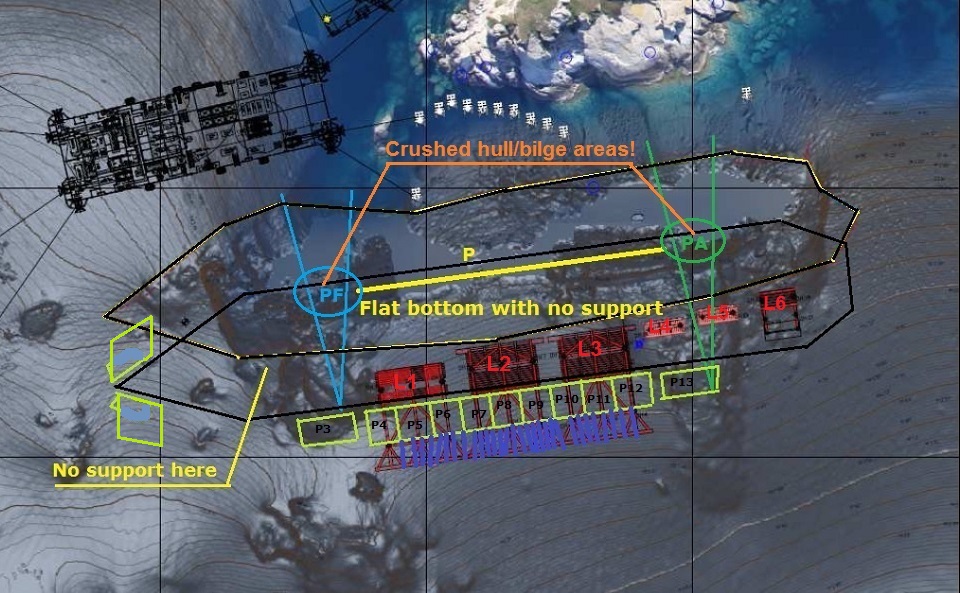

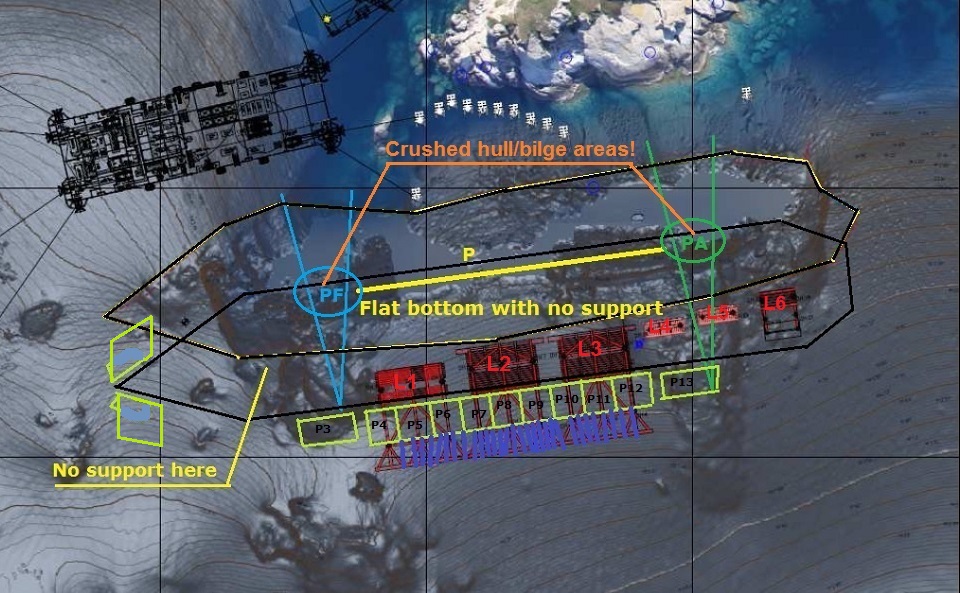

The hull consists of about 16 "watertight" compartments full of water, four of which (#4-7) are damaged due to the contact port side aft and another two at PA (#3) aft and PF (#12) forward damaged at bottom/bilge due to the capsize and parbuckling.

The "watertight" compartments have 25 illegal watertight doors fitted in the 15 bulkheads that probably are open, i.e. they are not "watertight". Actually these illegal doors sank the ship 2012.

However, if you make the thin, say 5 mm thick, #0 bulkhead deck airtight and ensure that the bulkheads below are "watertight", then you could push out 17.000 tons of water from the water filled hull compartments below using 0.6-0.8 bar compressed air ... and the ship floats by itself!

Furthermore with a loose bow section forward of PF described in point 35 below that can fall off, even if it is kept floating assisted by a "blister" (see below) still in place, the ship may break apart.

The #0 bulkhead deck can only carry say